The world's first demonstration of the high-efficiency hydrogen liquefaction by magnetic refrigeration

In hydrogen liquefaction by the magnetic refrigeration, the adiabatic

demagnetization method to generate temperature below 1 K is extended to

the high-temperature region.

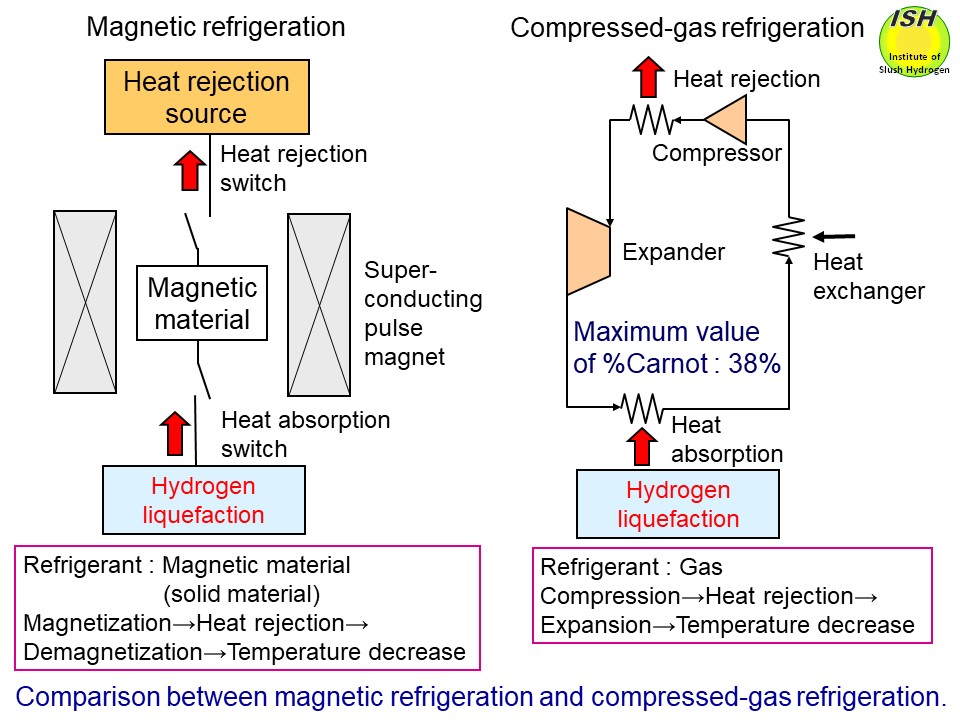

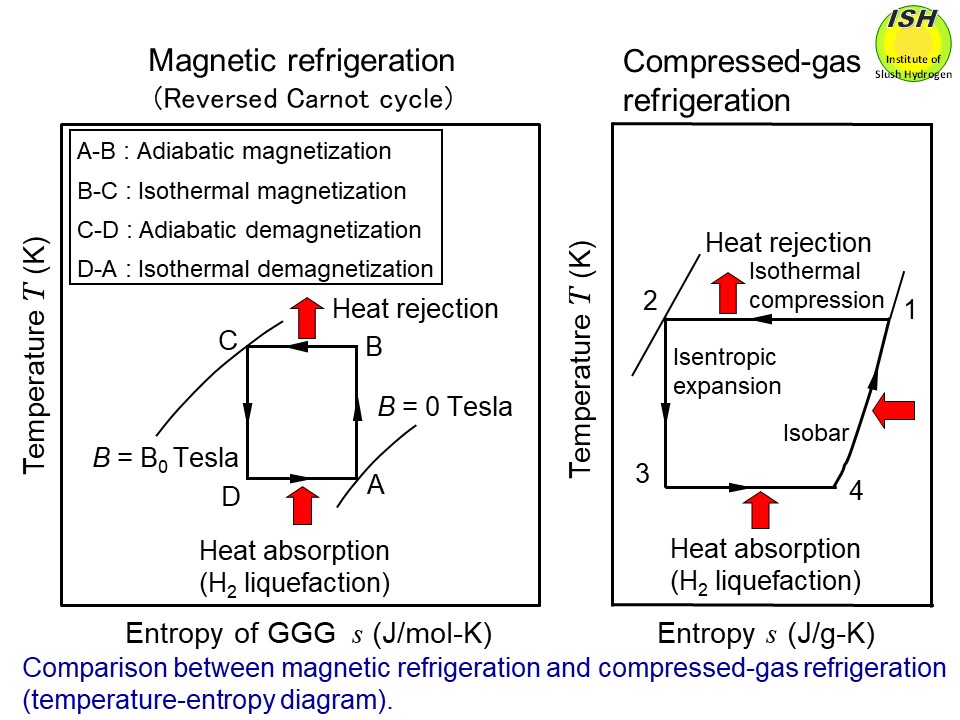

The principles of the magnetic refrigeration and the compressed-gas refrigeration

are illustrated in the above figure. The temperature-entropy diagrams of magnetic material and gas as a refrigerant

in liquefaction cycle are respectively presented in the above figure. The magnetic refrigeration for hydrogen liquefaction uses an external

magnetic field to magnetize and demagnetize a magnetic material in repeated

cycles, thus producing low temperatures through the magnetocaloric effect.

Since the magnetic refrigeration method can ideally realize the reversed

Carnot cycle, it is possible to achieve theoretically a higher %Carnot

efficiency* in contrast to the compressed-gas refrigeration method as noted

in the above figures [4].

The maximum efficiency is expected to be about 50% in terms of the %Carnot

efficiency*, compared to about 38% of the %Carnot efficiency for the world’s

largest hydrogen liquefier (liquefaction capacity: 60 ton/day) using the

compressed-gas method. Also, given the use of solid magnetic material,

which has much greater entropy density than gas, the liquefier can be made

compact.

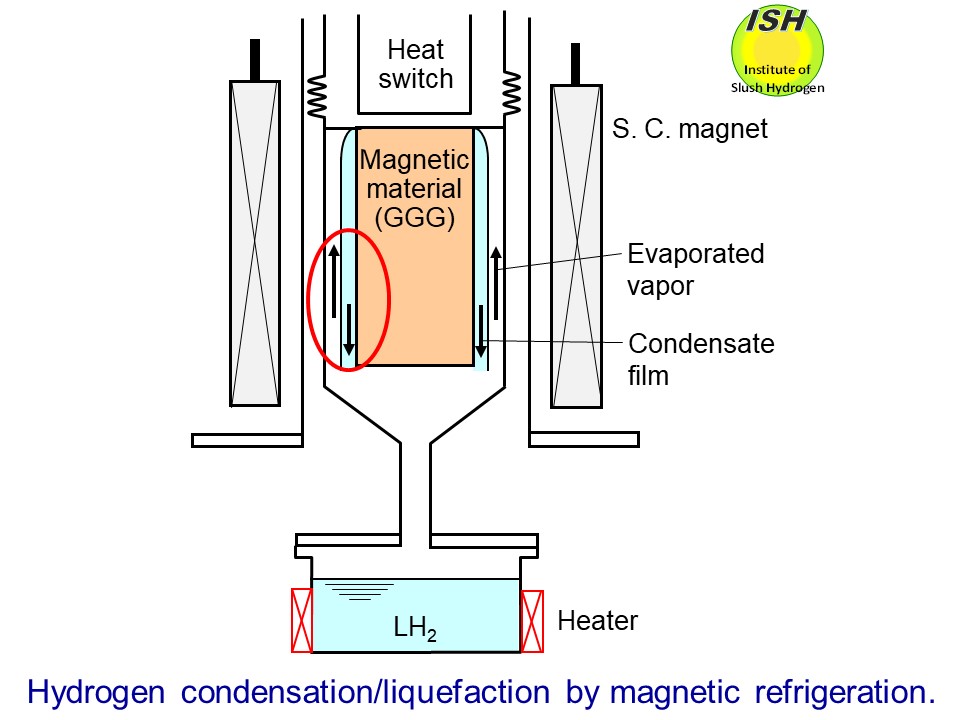

In the experiment, hydrogen gas evaporated in a liquid hydrogen vessel,

as shown in the figure below, was liquefied by using magnetic refrigeration. Gadolinium gallium garnet

(GGG: Gd3Ga5O12) was selected as a magnetic material. The magnetic refrigerator maimly

consists of a superconducting pulse magnet (the maximum field of 5 Tesla

and the maximum magnetization/demagnetization sweep rate of 0.36 T/s),

a Gifford-McMahon type refrigerator (UCR31W made by MHI) as a heat rejection

source (Th = 25 K), and a heat pipe as a heat absorption switch for hydrogen liquefaction

(Tl = 20.3 K) [8, 9]. In the thermal design of the high-performance heat pipe,

the Nusselt eq. was applied to evaluate the condensing heat-transfer coefficient

of hydrogen as described in "Hydrogen condensation and liquefaction".

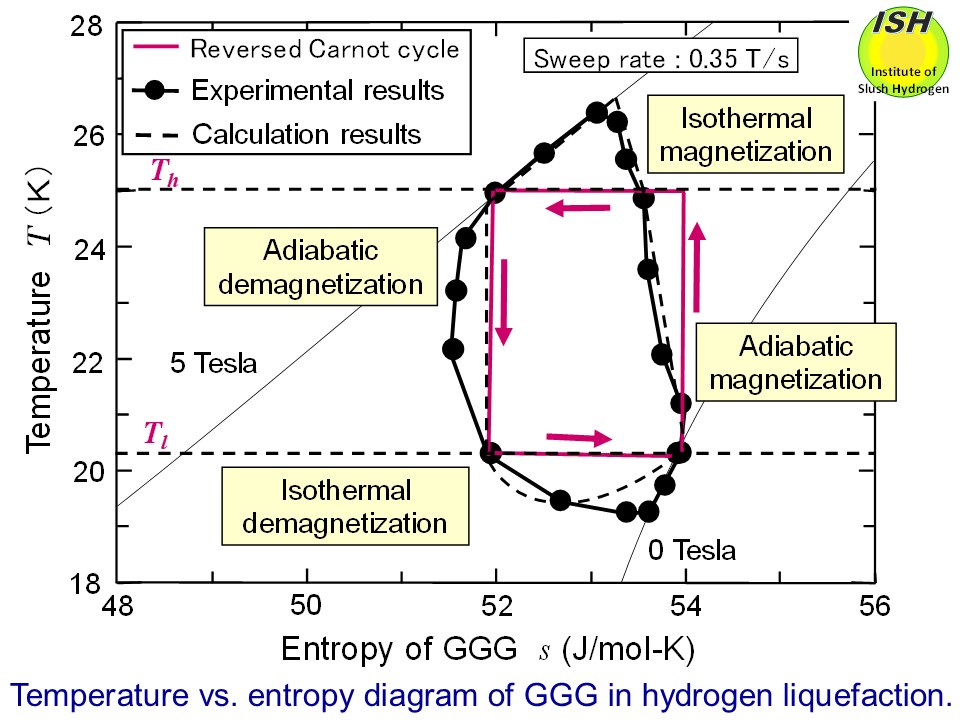

The temperature-entropy diagram of magnetic material (GGG) obtained in

the hydrogen liquefaction experiment at 0.35 T/s, the reversed Carnot cycle,

and the calculation results using a simulation model are illustrated in

the figure below. The reasons the ideal reversed Carnot cycle indicated as a rectangle

cannot be realized are the insufficient heat-transfer performance of the

heat absorption and heat rejection switches, and the influence of uncondensed

hydrogen gas (continuously evaporating in the liquid hydrogen vessel) around

the magnetic material.

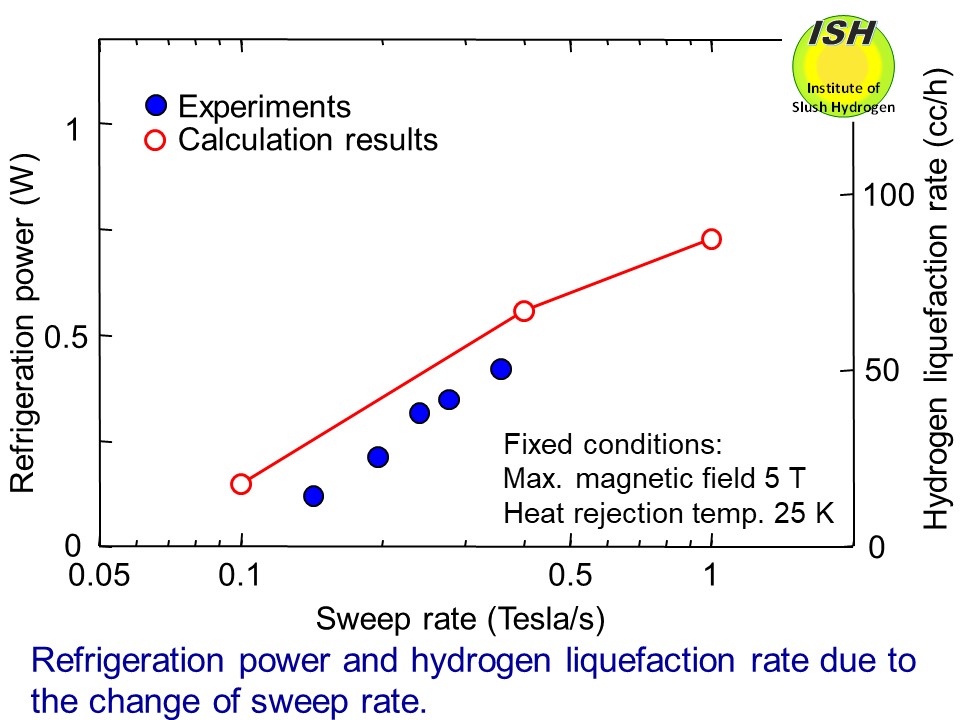

In the hydrogen liquefaction experiment at the fastest magnetization/demagnetization

rate of 0.36 T/s, as shown in the figure below, the maximumrefrigeration power (at 20.3 K) of 0.4 W (liquefaction rate: 3.55 g/h or 50 cc/h) with the %Carnot

efficiency* of 37% and the liquefaction efficiency** of 78% was obtained.

The achievement of 37% for the %Carnot efficiency in a small-scale liquefaction

experiment (3.55 g/h or 50 cc/h) demonstrates the high efficiency of this

method.

The world’s first high-efficiency hydrogen liquefaction by the magnetic

refrigeration is also demonstrated [8, 9].

The details of the study and experimental results are given on "Web site" below.

For hydrogen liquefaction, a multistage magnetic refrigerator from room

temperature to liquid hydrogen temperature has been proposed, and research

and development work is in progress.A method has also been proposed for producing slush hydrogen from liquid

hydrogen, using magnetic refrigeration to produce temperature below 14

K.

* %Carnot efficiency: The ratio of the reversed Carnot work to the actual

work per unit mass liquefied. %Carnot efficiency = FOM (Figure of Merit)×100

(%).

** Liquefaction efficiency: The ratio of the rerigeration power of the

experiment to that of the reversed Carnot cycle at the refrigeration (or

liquefaction) temperature.

Details of our hydrogen liquefaction study by magnetic refrigeration are

shown here.

Temperature-entropy diagram of GGG, refrigeration power and hydrogen liquefaction rate