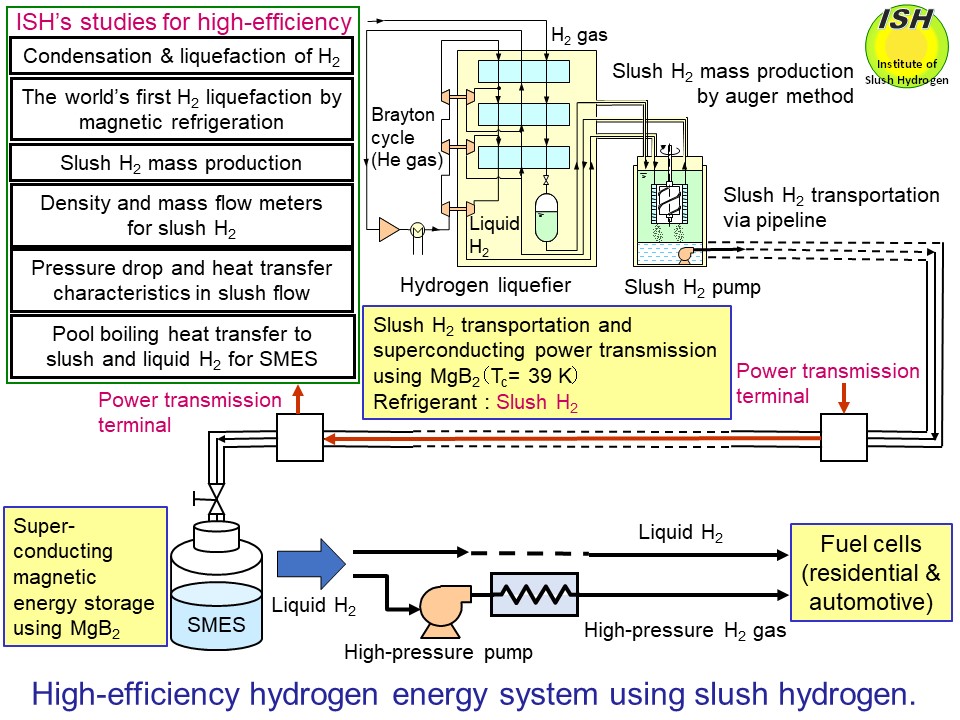

Development of the high-efficiency hydrogen energy system using slush hydrogen

Anticipated applications for slush hydrogen* include fuel cells, rocket

and space-plane fuels, and refrigerant for high-temperature superconducting

(HTS) equipment. With the rapid popularization of fuel cells, increasing

demand for electrical power due to the rise of information technology,

and the need to reduce greenhouse gas emissions [1, 2] **, Institute of Slush Hydrogen (ISH) has originally proposed the high-efficiency

hydrogen energy system using slush hydrogen, and has been engaged in related technological development work as illustrated

in the above figure [3-5].

When hydrogen is transported in the form of slush through long-distance

pipelines, in combination with the HTS electrical power transmission using

magnesium diboride (MgB2) ***, and the high-temperature superconducting magnetic energy storage

(SMES) at the terminal with liquid**** or slush hydrogen as the refrigerant,

both fuel and electrical power can be simultaneously transported and stored

with synergistic effect.

Slush hydrogen can be continuously produced by a combination of hydrogen

liquefier using the helium Brayton cycle and the auger method as shown

in the above figure. In the transportation of slush hydrogen via pipeline, integration with

HTS equipment using MgB2 enables the transport and storage of fuel and electricity simultaneously.

For transport via pipeline to a remote location, because heat inleak during

such transport would melt the solid hydrogen particles, it is predicted

that storage would be in the form of liquid hydrogen. The further utilization

of liquid or slush hydrogen as the refrigerant for the high-temperature

SMES at the destination end would simultaneously enable the storage of

electrical power and hydrogen fuel. Pumped liquid hydrogen is supplied

to household fuel cells and hydrogen stations for fuel cell vehicles.

Fuel cell vehicles take onboard 70 MPa high-pressure hydrogen gas, and

the production of 100 MPa gas is anticipated. The actual work per unit

mass for gas compression associated with this pressure level is about the

same as that per unit mass for hydrogen liquefaction using low-pressure

hydrogen gas, due to reduced compression efficiency. Thus, hydrogen could

be in the form of slush or liquid hydrogen for transport and storage, and

at the supply point such as a hydrogen fuel station, pumped liquid hydrogen

with much less power consumption for pressurization would be vaporized

for supply of high-pressure gas hydrogen as needed.

At the same time, the recent state of development with respect to superconducting

technology is encouraging. In the US city of Albany, New York, a superconducting

power transmission system using a bismuth-based HTS material with liquid

nitrogen as the refrigerant was successfully introduced in 2006, indicating

the first time for such a system to be connected to a working power grid.

Also at a factory in the Japanese city of Kameyama in Mie Prefecture, a

commercial SMES system with liquid helium as the refrigerant was set up

to protect a liquid crystal panel production line from sudden voltage drops

in 2004. Both examples demonstrate the practical applicability of the hydrogen

energy system proposed by ISH.

To bring about the practical realization of this hydrogen energy system,

ISH has been engaged in research and development work as indicated in the upper left corner of the above figure.

ISH’s main achievements thus far are summarized as follows:

-

The world's first verification of agreement of the condensation heat transfer to hydrogen with the Nusselt theory [6, 7],

-

The world’s first demonstration of the high-efficiency hydrogen liquefaction using magnetic refrigeration [8, 9],

-

Demonstration of the mass production technology of slush hydrogen using an auger method [10, 11],

-

Research and development of high-accuracy density and mass flow meters for slush hydrogen with an innovative structure, considering the behavior of solid particles [12-16],

-

The world's first demonstration of the simultaneous occurrence of pressure drop reduction and heat transfer deterioration in slush nitrogen flow for various types of pipe such as circular, square and triangular pipies (the Reynolds' analogy), and the pressure drop reduction in slush nitrogen flow for corrugated, converging-diverging and elbow pipes [5, 17-22], and the development of a three-dimensional numerical simulation code (SLUSH-3D) to clarify flow and heat-transfer characteristics in slush hydrogen and slush nitrogen flows [5, 23, 24], and

-

Pool boiling heat transfer to slush and liquid hydrogen for the high-temperature SMES [25].

At the same time, ISH has been engaged in related technological development

work as follows:

-

Pressure drop and heat transfer characteristics of boiling liquid nitrogen in pipe flow [26, 27], and

-

Cavitation flow instability of subcooled liquid nitrogen in converging-diverging nozzle flow [28, 29].

* The triple point temperature coexisting liquid, solid, and vapor of

slush hydrogen is -259℃ or 14 K. The slush hydrogen temperature coexisting

liquid and solid is, depending on the pressure, higher than -259℃ or 14

K.

** Numbers in brackets show the numbered references in “References”.

*** MgB2: The superconducting transition temperature Tc is below 39 K

**** The normal boiling point temperature of liquid hydrogen is -253℃

or 20 K.

Message from Representative

Efforts are currently underway in Europe, North America, and Asia aimed

at the realization of hydrogen energy society, including household fuel

cells, fuel cell vehicles, and the full-scale spread of the infrastructure

network of hydrogen stations for fuel cell vehicles.

In Japan, sales of the world’s first fuel cell cogeneration system for

household use (ENEFARM) began in 2009. General sales of fuel cell vehicles

(TOYOTA MIRAI) began in 2014, with full-scale popularization envisioned

for 2030.

Considering the world’s trend for realizing the hydrogen energy society,

with the objective of practical realization of this high-efficiency hydrogen

energy system, ISH is carrying out the research and development work associated

with slush hydrogen.