High-accuracy densimeter and mass flow rate meter for slush hydrogen and slush nitrogen

By measuring the fluid temperature, pressure and volumetric flow, it is

easy to determine the density or mass flow rate of single-phase fluids

such as liquid hydrogen. However, for slush hydrogen, because density varies

in accordance with the solid fraction, it is necessary to measure the solid

fraction directory.

Regardless of the method being considered, the influence of solid particles

on density and flow velocity measurement must be clarified to improve measurement

accuracies. Given the objective of high accuracy in density and mass flow

rate measurements, new densimeter and mass flow rate meter structures are considered. These

approaches are based on changes in the specific dielectric constant, or

changes in the microwave propagation properties, due to variation in the

solid fraction [14, 15, 16].

High-accuracy densimeter for slush hydrogen

Capacitance-type densimeter

In the case of solid particles mixed in a liquid, such as with slush hydrogen,

it is important to consider the behavior of the solid particles in terms

of electrode configuration if the accuracy of capacitance-type densimeter

is to be improved.

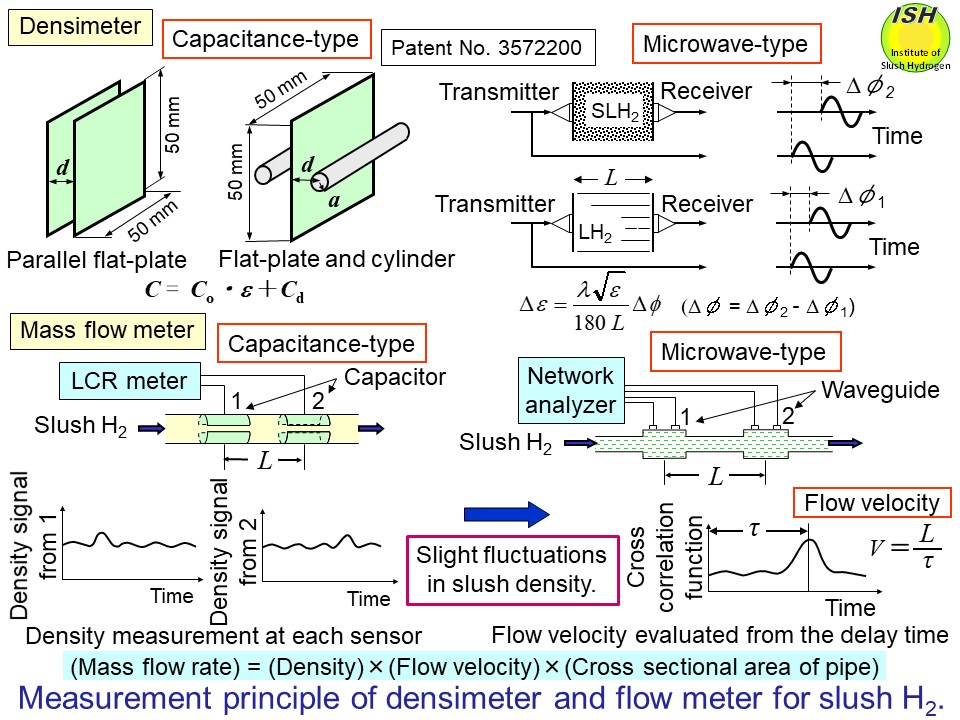

The above figure illustrates the principles associated with the parallel flat-plate type

for single-phase liquid, and the flat-plate and cylinder type for slush

[12,16].

A combination design featuring a flat-plate together with two cylinders

allows solid particles to easily enter between the electrodes, with a simple

construction that offers high accuracy. The relationship between the capacitance C of the capacitance-type densimeter and the specific dielectric constant

ε is expressed in the above figure. Here, C0 and Cd are fixed constants measured in advance in liquid hydrogen. The measurement

of C for the densimeter placed in slush hydrogen allows determination of ε. The volumetric solid fraction can be calculated from the specific dielectric

constants εs and εl of solid and liquid hydrogen, while the density of slush hydrogen can

be determined from densities of the solid and liquid.

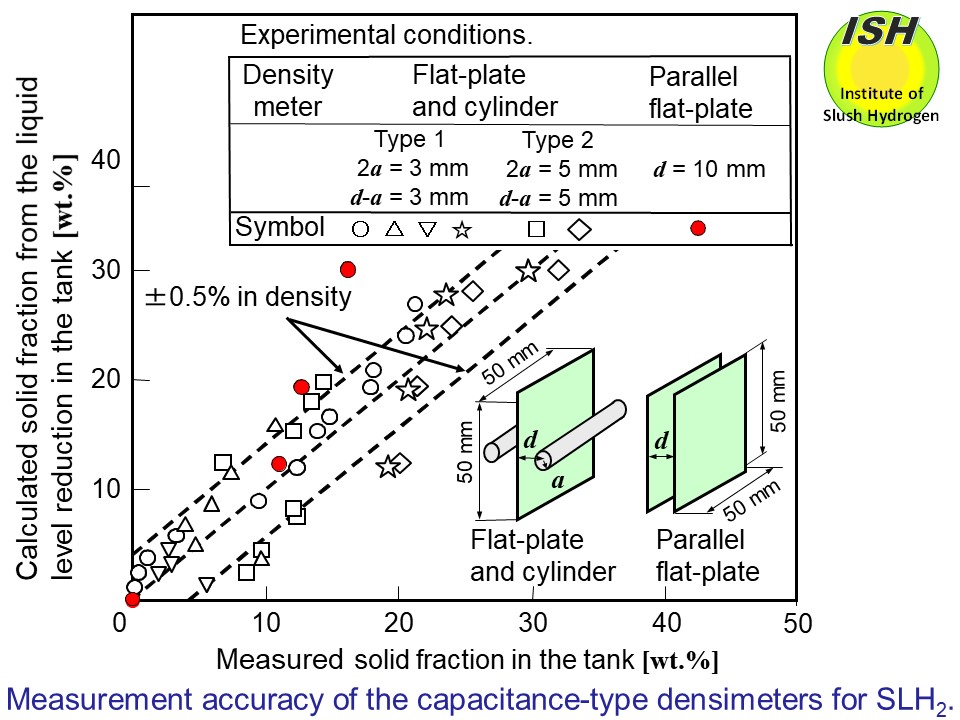

The figure below presents the solid fraction measurement results for two varieties of flat-plate

and cylinder type electrodes, and for a parallel flat-plate type. In the

case of the parallel flat-plate type, as the solid fraction increased,

the solid particles were unable to sufficiently enter within the electrode

structure, and the solid fraction obtained was lower than the actual density.

In contrast, almost all the measured results for the flat-plate and cylinder

type were in good agreement with the calculated value. The solid fraction

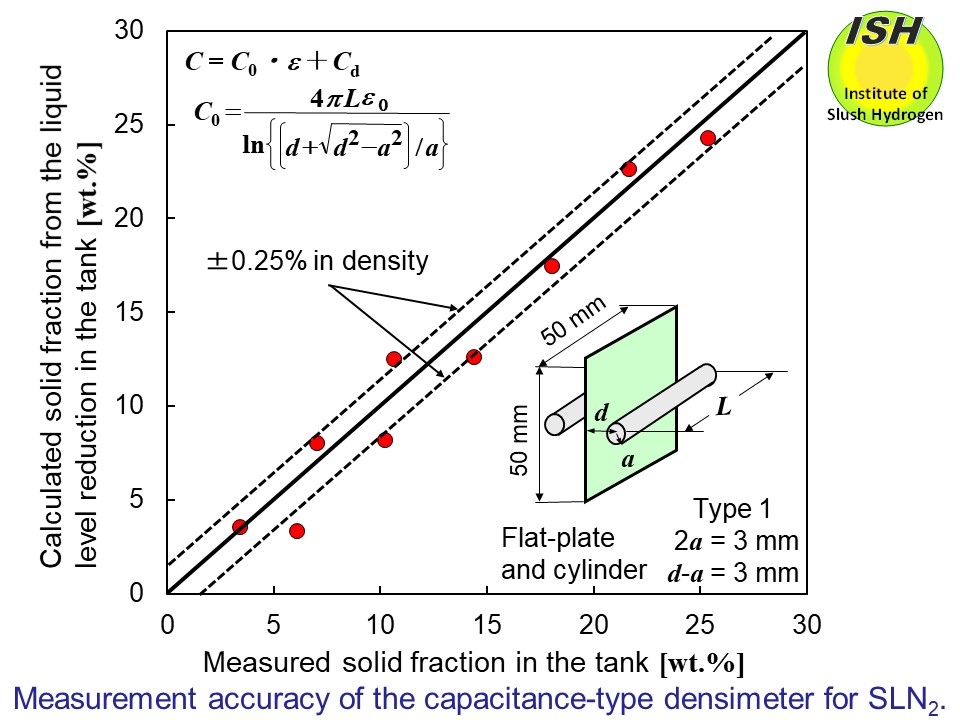

measurement results of slush nitrogen for the flat-plate and cylinder type

are also shown in the figure below. In the cases of slush hydrogen and slush nitrogen, density measurement

accuracies were within ±0.5% and ±0.25%, respectively [5, 12].

The main reasons for the difference in measurement accuracy are, in the

case of slush nitrogen, both the specific dielectric constant and the difference

in specific dielectric constant between solid and liquid are larger than

those of hydrogen, and the measurement accuracy increases as shown in the figure below.

Microwave-type densimeter

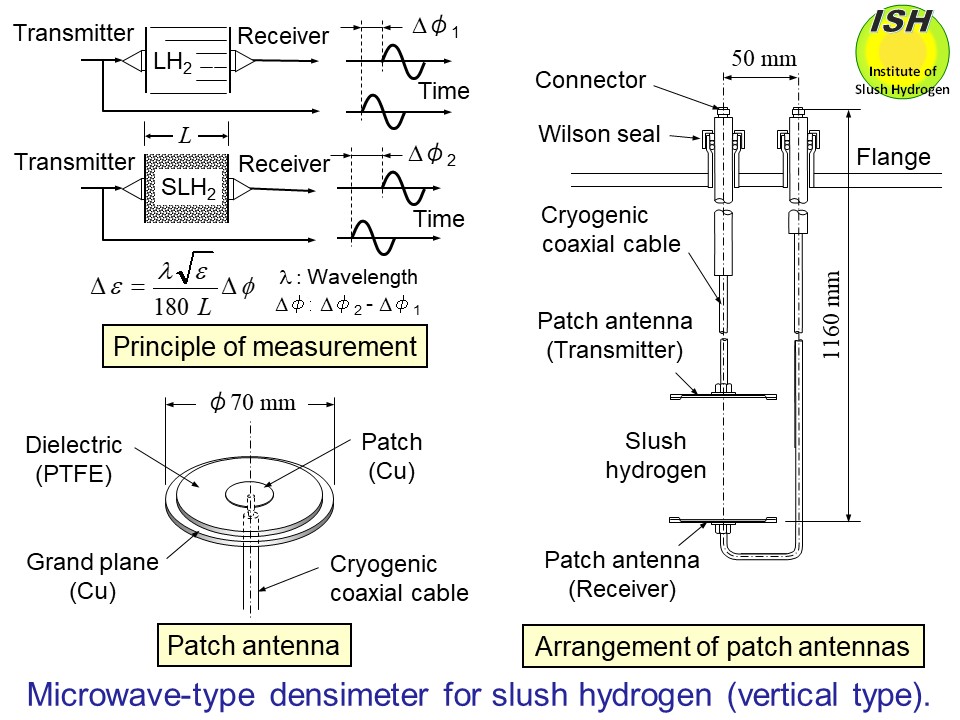

The microwave-type densimeter, as shown in the measurement principle figure, consists of micro-wave transmitter and receiver antennas, employing a

network analyzer to measure the phase shift in the microwaves propagated

between the antennas. This new type has been developed, and the measurement

is done with respect to the phase shifts ΔΦ1, ΔΦ2 in the microwaves propagated between the antennas in liquid and slush

hydrogen, respectively. The relationship between the phase-shift difference

ΔΦ = ΔΦ2-ΔΦ1 and the change in the specific dielectric constant Δε for liquid and slush hydrogen on the other is expressed in the above figure.

Here, λ is the microwave wavelength and L is the distance between the transmitter and receiver antennas.

Ellerbruch [50] measured the density of slush hydrogen in a tank using

the conventional method with a waveguide and horn antenna. In this method,

because the slush hydrogen enters inside the waveguide and horn antenna,

there is the disadvantage that the density in the tank cannot be precisely

measured. He reports the density measurement error of approximately 2%

in comparison to gamma ray measurement results. The figure below illustrates the patch antenna and cryogenic coaxial cable arrangement

used to introduce the microwaves [13,16], which is shaped so as to have

no opening, thereby eliminating the error that occurred in using the method

reported by Ellerbruch.

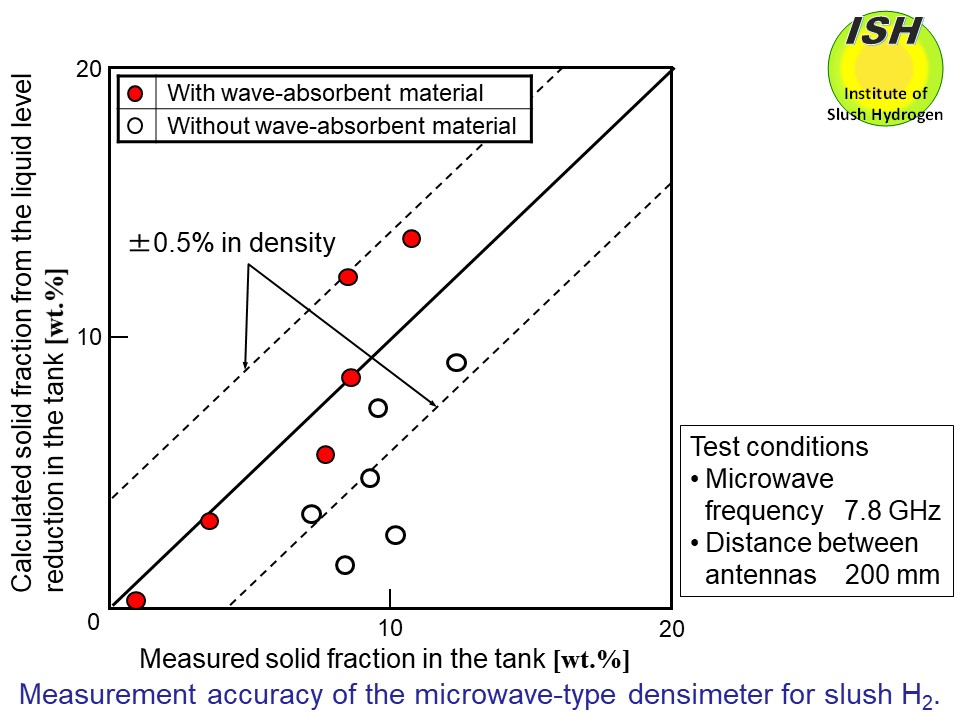

Density measurement tests were conducted in the same manner as for the

capacitance-type densimeter [12]. In addition, in order to reduce the reflection

of microwaves from the inner wall of the tank, tests were also carried

out with respect to the placement of the wave-absorbent material, consisting

of polyurethane foam impregnated with carbon. The figure below indicates the comparison of measured solid fraction values with calculated

solid fraction values obtained from the reduction of liquid hydrogen. Because

the inner diameter of the tank is only 240 mm in the case without the microwave-absorbent

material, the densimeter measurement results show a certain amount of measurement

error due to the influence of microwaves reflected from the inner wall.

This scattering is low in the case where the microwave-absorbent material

was used, and the accuracy of within ±0.5% was obtained in comparison with

the calculated results when converted to density.

High-accuracy mass flow rate meter

Ellerbruch [50] developed a microwave Doppler flowmeter to measure the

mass flow rate of slush hydrogen. In this method, the waveguide and horn

antennas were placed on opposite sides of a pipe flow section, and both

were filled with Teflon to prevent the solid particles from entering. The

velocity measurement error of approximately 10% is reported.

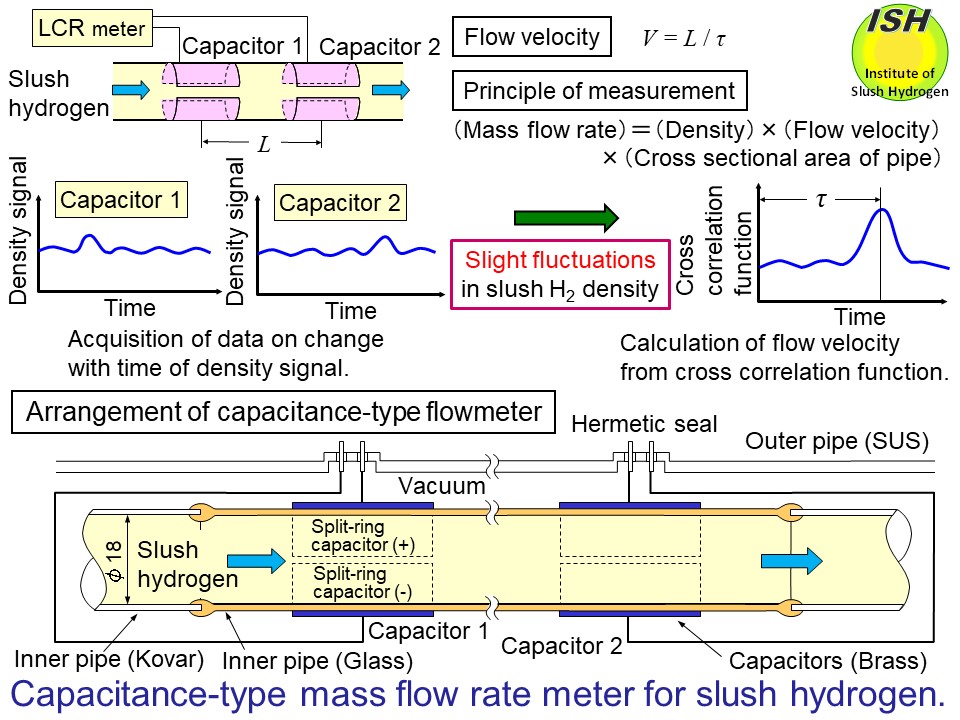

The new measurement principles of the capacitance-type and microwave-type

mass flow rate meters in pipe flow are shown in the measurement principle figure. These allow the determination of mass flow rate from the measurement

of density and flow velocity of slush hydrogen.

A noteworthy aspect of flow velocity measurement is the slight fluctuation

in the distribution of solid particles, i.e., slush hydrogen density fluctuation

[14, 15, 16].

First, capacitance-type and microwave (waveguide) -type densimeters are

placed at two locations along the pipe flow, and the density is measured

using the LCR meter* and network analyzer, respectively. Then, the flow

velocity V is calculated from the delay time τ where the cross-correlation function for the density measurement signals

from the two locations is at a maximum, together with the distance L between the densimeters, such that the mass flow rate can be determined.

Since these methods do not utilize any moving parts such as a turbine

flow meter, there is no need to install precooling pipes and valves.

* LCR meter: Equipment for measuring inductance (L), capacitance (C) and resistance (R). In the experiment, the capacitance (C) is measured.

Capacitance-type mass flow rate meter

The figure below illustrates the principle and structure of capacitance-type flowmeter

[14,16]. Capacitance-type densimeters were placed along upstream and downstream

pipes with split-ringtype capacitors attached at two locations on the pipe

wall. Changes in the capacitance between the capacitors were measured using

an LCR meter. The density is determined from the change in capacitance

(i.e., the specific dielectric constant change) between the capacitors;

however, the difference in the specific dielectric constant of the liquid

and solid at the triple point of hydrogen (52.8 Torr, 13.8 K) is no more

than 2.7%. Thus, the capacitance characteristics were calibrated at the

temperature of liquid hydrogen for improved accuracy.

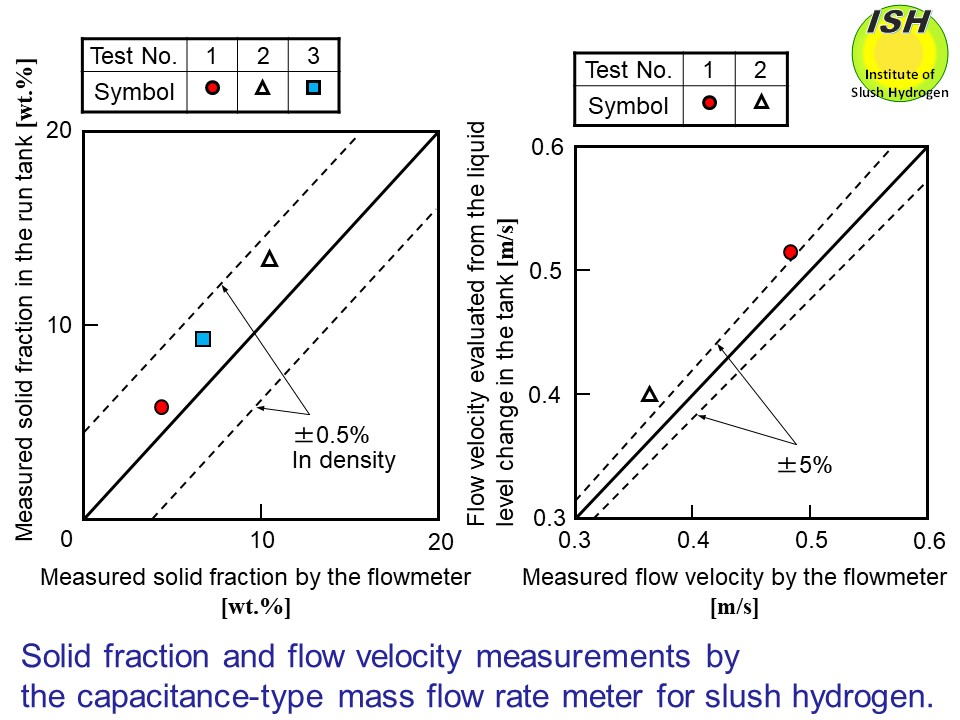

The figure below presents the results of the solid fraction and the flow velocity measured

in the tank and those measured using the flowmeter. The number of measurements

was low, such that a definitive statement cannot be made, but the following

conclusions can be drawn. First, the accuracy of the capacitance-type (flat-plate

and cylinder type) densimeter installed in the tank is about ±0.5%. And,

as the accuracy of within ±0.5% was confirmed in separately conducted density

measurement tests of the flowmeter alone, which are not reported here,

the density measurement accuracy of the flowmeter is also estimated to

be about ±0.5% from the results shown in the figure below. The results

indicated in the figure show a difference of about 10% between the flow

velocities measured by the flowmeter in the test section and that calculated

from the liquid-level change in the tank of the flow test apparatus, and

the main cause of this error is considered as follows. Since the flow velocity

measurement error with respect to measurement of the liquid-level change

within the tank of the flow test apparatus is estimated to be ±5% at a

flow velocity of 1 m/s. Furthermore, the time resolution of the LCR meter

used to measure the capacitance of the densimeter was 0.124 s, i.e., the

measurement time points cannot be made at closer intervals than 0.124 s.

For example, in the case of the delay time of τ = 0.496 s obtained in the experiment, a simple calculation of 0.124/0.496

= 0.25, such that a maximum measurement error of ±25% is predicted. Accordingly,

the use of an LCR meter with better time resolution would almost certainly

result in improved velocity measurement accuracy.

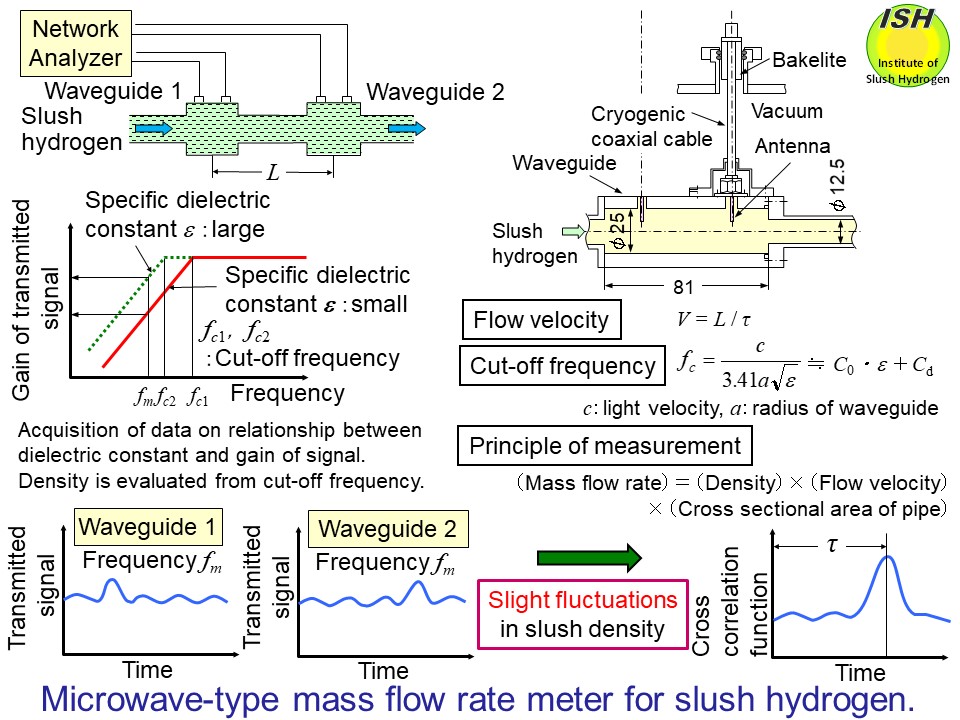

Microwave-type mass flow rate meter

The figure belowillustrates the principle of mass flow rate measurement system using the

microwave (waveguide) method [15, 16]. The main structural elements consist

of circular waveguides placed at two points on the upstream and downstream

slush hydrogen flow pipe (12.5 mm inner diameter) and a network analyzer

for waveform analysis. This waveform analysis using the network analyzer

allows the calculation of the gain between the signals transmitted and

received by the waveguides.

The relationship between the specific dielectric constantεof the medium contained in the waveguide (slush hydrogen) and the frequency

fcby which the gain corresponding to the microwave transmission signal passing

through the waveguide falls off like a step function (i.e., the cut-off

frequency) is as indicated in the figure. The density measurement of slush

hydrogen is made possible by the fact that the cut-off frequency changes

with the specific dielectric constant of slush hydrogen in the waveguide.

Since the difference between the specific dielectric constants of liquid

and solid is small at the triple point of hydrogen, the relationship above

can be approximated as follows:fc=C0・ε+Cd

In order to improve the density measurement accuracy, examination of precision

was carried out in advance using the waveguide as a densimeter for slush

hydrogen. Also, using the change in the specific dielectric constant that

occurred during the evacuation of liquid hydrogen when slush hydrogen was

produced in the flow test, the relation between the specific dielectric

constant and the cut-off frequency was measured, and the coefficients C0and Cdwere obtained using the least squares method. Next, considering that the

same rate of change would hold true for slush hydrogen, the specific dielectric

constant was determined from the cut-off frequency of the slush hydrogen

flow test; the solid volume ratio occupied in slush hydrogen was calculated

from the specific dielectric constants of solid and liquid hydrogen at

the triple point (εsand εlare known), and the density could thus be determined. With respect to flow velocity,

as illustrated in the figure, even when the frequency is fixed at fm, lower than the cut-off frequency for slush hydrogen, the gain between

the signals transmitted and received by the waveguides changes in the same

manner as the change of specific dielectric constant within the waveguide,

such that the measured gain could be used to calculate the cross correlation

function, thereby enabling the determination of the flow velocity. This

method makes the gain measurement time period as short as possible, and

therefore enables to improve the measurement accuracy of flow velocity.

The precise density measurement using a cut-off frequency is made before

and after the measurements of the slush hydrogen flow velocity.

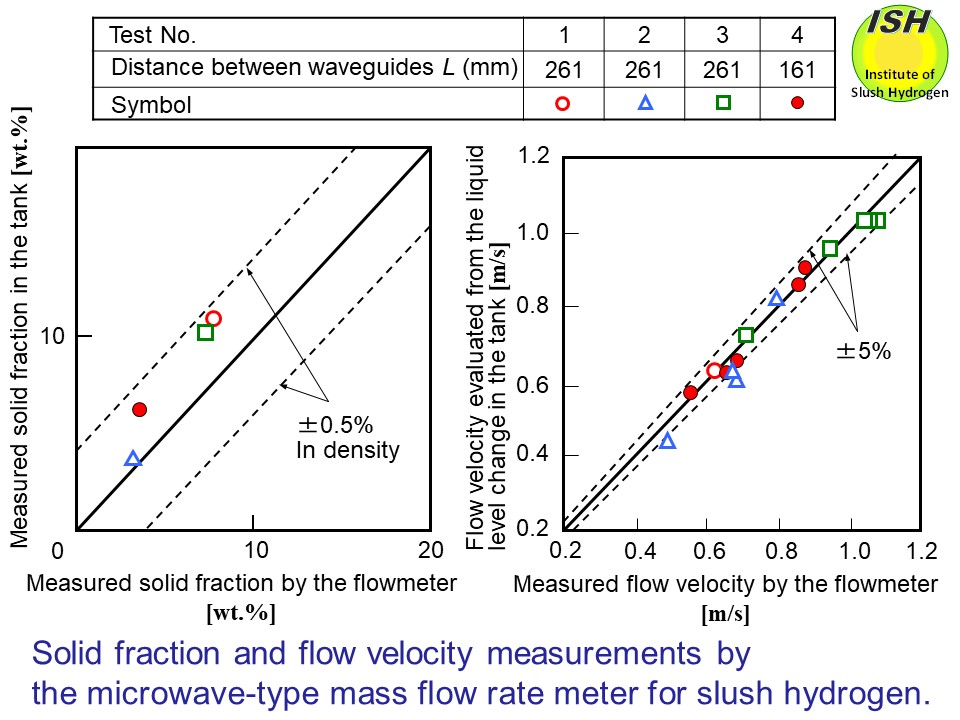

The figure below shows the results of the solid fraction and the flow velocity measured

in the tank of the flow test apparatus and those measured using the flowmeter.

Accordingly, the following conclusions can be drawn from the results shown

in the figure. The accuracy of the capacitance-type (flat-plate and cylinder

type) densimeter installed in the tank is about ±0.5%. And, as the accuracy

of within ±0.5% was confirmed in preparatory density measurement tests

of the flowmeter alone, the density measurement accuracy of the flowmeter

is also estimated to be about ±0.5% from the results shown in the figure.

The results indicated in the figure show a difference of about 5% between

the flow velocity measured by the flowmeter in the test section and that

calculated from the liquid-level change in the run tank. Note that the

0.0011 s time resolution of the network analyzer used to measure the density

signal (gain) of the densimeter was superior to the LCR meter. For example,

in the case of the delay time of τ = 0.330 s, a simple calculation of 0.0011/0.330 = 0.003, such that a maximum

measurement error of ±0.3% is predicted, making the flow velocity measurement

error extremely small. Since the flow velocity measurement error with respect

to measurement of the liquid-level change within the run tank of the flow

test apparatus is estimated to be ±5% at a flow velocity of 1 m/s, the

newly developed microwave-type flowmeter may indicate a high-accuracy method

of mass flow rate measurement for slush hydrogen.

Density and mass flow rate measurement technologies were reported for

slush hydrogen. As a result, measurement accuracy of about ±0.5% was confirmed for capacitance-type

and microwave-type densimeters. Use of an LCR meter having the superior

time resolution for the capacitance-type flowmeter may enable improved

measurement accuracy. It was also suggested that the newly developed microwave-type

flowmeter may allow high accuracy mass flow rate measurement.